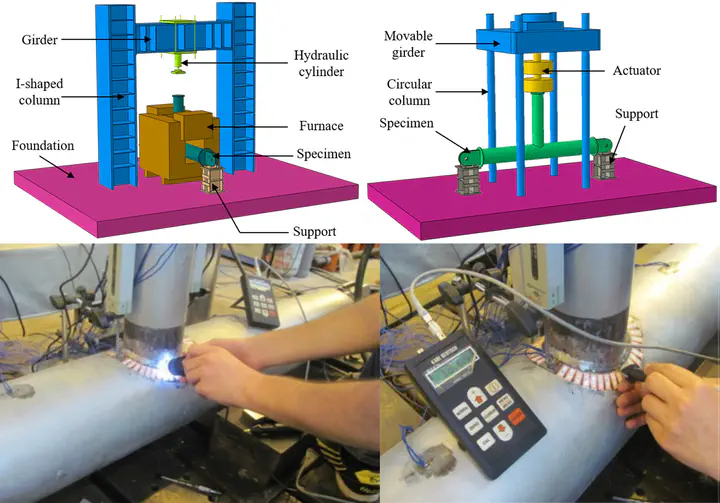

Fire Resistance Behavior of Welded Tubular Structures (2013 - 2016)

Welded tubular structures have been widely used in large-span structures, such as stadiums, television towers, airport terminals, and offshore jacket platforms. In these structures, tubular joints serve as essential components to connect different branches. Steel material is susceptible to high temperatures, which makes the tubular joints vulnerable under fire conditions. The relevant design guidelines (such as CIDECT and Eurocode 3) provide limited details on the performance of these joints at elevated temperatures. To enhance the understanding of the tubular joints’ fire resistance behavior, this project involved a series of full-scale experimental tests and disclosed the joint’s failure mechanism, force-deformation development, and thermal response. Then a generic finite element framework was proposed to simulate the tubular joint’s response during the entire firing process, including pre-fire, heating, cooling, and post-fire stages. After validating the finite element simulation against the experimental data, many finite element models were constructed to quantify the influence of various joint parameters on fire resistance. Based on the data collected from the experimental tests and numerical simulations, a series of equations were proposed to predict the maximum temperature various joints could sustain without losing too much strength. Such equations fill the blank area of the associated design guidelines.