Fire resistance behavior of T-stub joint components under transient heat transfer conditions

Test Rig and Model Assessment

Test Rig and Model Assessment

Abstract

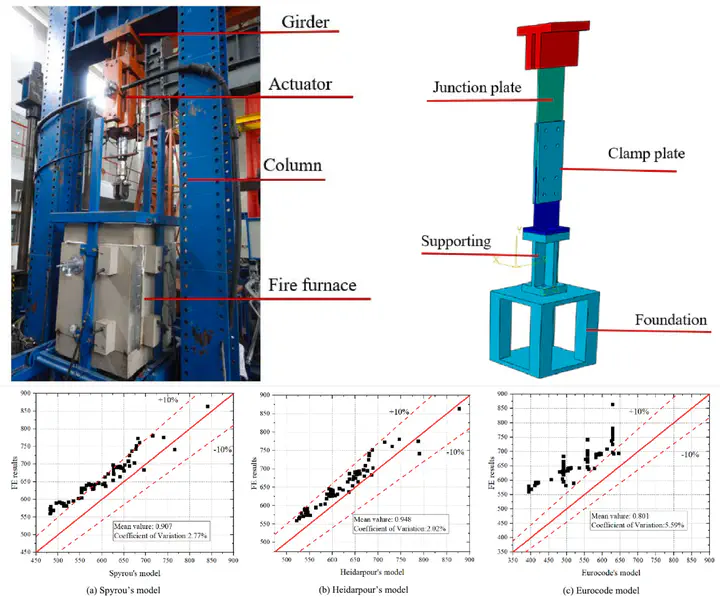

The fire resistance behavior of T-stub joint components at elevated temperatures was experimentally and numerically investigated. To start, twelve T-stub specimens with different geometric properties were tested to failure under the transient heat transfer condition. The failure modes of these specimens were classified into three categories: complete yielding of the flange, pure bolt fracture failure, and the combination of the flange yielding and bolt fracture. The displacement-temperature curves obtained from the experiment were idealized as three segments, and the associated critical temperature, ultimate temperature, and deformation capacity were evaluated. Then the finite-element (FE) models of T-stubs were developed to simulate their responses under the transient heat transfer condition using ABAQUS (version 6.18). The comparison of critical temperature, failure temperature, and deformation capacity indicated that the FE analysis was in good agreement with the experimental results. A comprehensive parametric study was subsequently carried out to quantify the effects of various geometric parameters and load ratios on the response of the T-stubs under fire conditions. Meanwhile, a comparative assessment between the transient and steady analyses proves the reliability of the transient test method. Based on the data collected from the experiment and FE analysis, three analytical models (including the Spyrou’s model, the Heidarpour’s model, and the one recommended by Eurocode 3-1-8) were critically examined to reveal their performance in estimating the ultimate temperature and deformation capacity of T-stubs.