Experimental investigation on the fatigue behaviour of heat-treated tubular t-joints

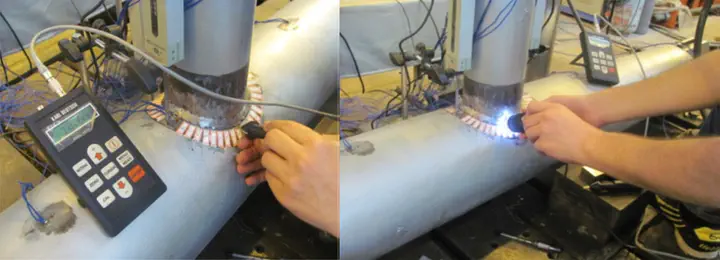

Strain Measurement

Strain Measurement

Abstract

The stress distribution along the weld toe (SCF test) and the fatigue life of tubular T-joints (Fatigue test) were experimentally investigated in this study. Three specimens with identical geometric properties were tested to failure under fatigue cyclic loading at the brace end. Prior to the loading tests procedure, SCF and Fatigue tests, two specimens went through one cycle of heating and cooling naturally. The SCF test results showed that the maximum Stress Concentration Factor (SCF) occurred at the chord saddle for all the specimens. The fatigue cracks were initiated at the chord saddles of the three tested specimens. The fatigue test results showed that the fatigue life was longer the higher the target maximum temperature was. The development of the crack aspect ratio with the normalised crack length was discussed among the specimens. Finally, the fatigue life results obtained from the experiment compared with those from CIDECT and API guidelines.