Fire-resistance behavior of completely overlapped tubular joints under lap brace axial loading

Experimental Setup and Finite Element Simulation Framework

Experimental Setup and Finite Element Simulation Framework

Abstract

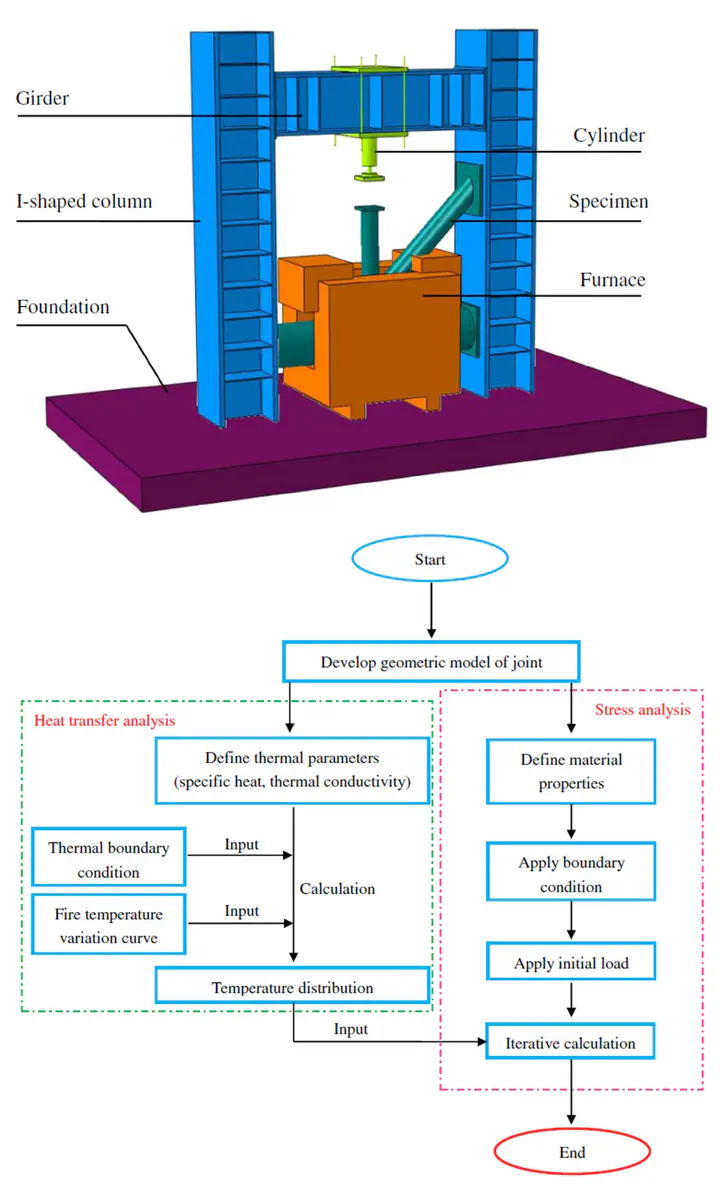

The fire resistance behavior of completely overlapped tubular joints was experimentally and numerically investigated. Three completely overlapped tubular joint specimens with different geometric properties were tested to failure under constant lap brace axial loads at elevated temperatures. The failure modes of the three specimens were identified as the local indentation with plastification at the through brace face joining the lap brace. No sign of local deformation on the chord was observed. The finite-element (FE) models of completely overlapped tubular joints were developed based on the sequentially coupled thermal-stress analysis using ABAQUS (version 6.10). The comparison of the critical temperature, fire endurance time, and failure mode showed that the FE analysis was in good agreement with the experimental results. A parametric study was subsequently carried out to quantify the effects of various geometric parameters of the joints under fire conditions. An existing equation was adapted from the Comité International pour le Dévelopment et 1’Etude de la Construction Tubulaire (CIDECT) to predict the critical temperature of the joints. Based on the data obtained from the experiment and the FE analysis, the adapted equation predicted reasonably well the critical temperature of the completely overlapped tubular joints under lap brace axial loading.